The nuclear accident at Fukushima-Daiichi nuclear power complex in 2011 has started a discussion within the nuclear materials community regarding the safety and the operational limits of Zirconium alloys nuclear fuel rods under extreme conditions.

Zirconium is the holy grail of Light-Water Reactors (LWRs) and it is directly responsible for the success of nuclear reactors technology worldwide. Deeply researched by Admiral Hyman G. Rickover and his team in early 1960s [1], this success is mainly attributed to the properties that Zr and its alloys have within the context of a nuclear reactor operation: desirable mechanical properties, good corrosion resistance and low thermal neutron absorption cross section [2-3]. The last topic is of paramount importance as if the nuclear fuel rod material is relatively transparent to thermal neutrons, the efficiency of a nuclear reactor is not penalised (that is the case for stainless steels).

In the Fukushima-Daiichi nuclear power complex, the nuclear reactor lost its coolant material (i.e. water) due to the occurrence of external events: an earthquake and a tsunami [4]. In this operational condition, the temperature inside the nuclear reactor core rose abnormally and the known oxidation reaction between steam and the Zr rods have generated huge quantities of hydrogen gas (H2). The accumulation and leak of H2 was the cause behind several explosions in the nuclear power complex.

Replacing Zirconium in the already consolidated nuclear technology would require the design, test and licensing of a new metallic alloy: a task that would require millions of dollars in investments and in evaluation and tests as well as countless efforts to find a material with similar properties to Zr. One possible solution has been to coating Zirconium alloys with protective materials.

Conventional Titanium Nitride (TiN) and Titanium Aluminium Nitride (TiAlN) thin films are currently some candidate systems [5-6], but recently, the demonstrated feasibility for the synthesis of high-quality nanocrystalline high-entropy alloy thin films has added another perspective regarding protective coatings on Zirconium alloys [7]. Highly-concentrated alloys have been subjected to intense research in the past three years and due to their unique properties and superior resistance to energetic particle irradiation, these alloys are currently looking for some space to be applied in real nuclear systems.

Clearly coatings on Zirconium alloys will have to exhibit compatibility with the HCP matrix and prove suitable tribological properties. They will also have to cope with the limitations of materials for nuclear structures: reduced activation, good corrosion resistance, improved radiation resistance and desirable mechanical properties. Therefore, these new efforts towards new accident tolerant fuel concepts are just expressing how important the materials research is for our civilisation and how consolidated technologies can always be improved, modified and enhanced upon advances in technology.

References

[1] RICKOVER, Hyman George; GEIGER, Lawton D.; LUSTMAN, Benjamin. History of the development of zirconium alloys for use in nuclear reactors. Energy Research and Development Administration, 1975.

[2] ZAIMOVSKII, A. S. Zirconium alloys in nuclear power. Soviet Atomic Energy, v. 45, n. 6, p. 1165-1168, 1978.

[3] GRIFFITHS, M. A review of microstructure evolution in zirconium alloys during irradiation. Journal of Nuclear Materials, v. 159, p. 190-218, 1988.

[4] HOLT, Mark; CAMPBELL, Richard J.; NIKITIN, Mary Beth. Fukushima nuclear disaster. Congressional Research Service, 2012.

[5] ALAT, Ece et al. Ceramic coating for corrosion (c3) resistance of nuclear fuel cladding. Surface and Coatings Technology, v. 281, p. 133-143, 2015.

[6] ALAT, Ece et al. Multilayer (TiN, TiAlN) ceramic coatings for nuclear fuel cladding. Journal of Nuclear Materials, v. 478, p. 236-244, 2016.

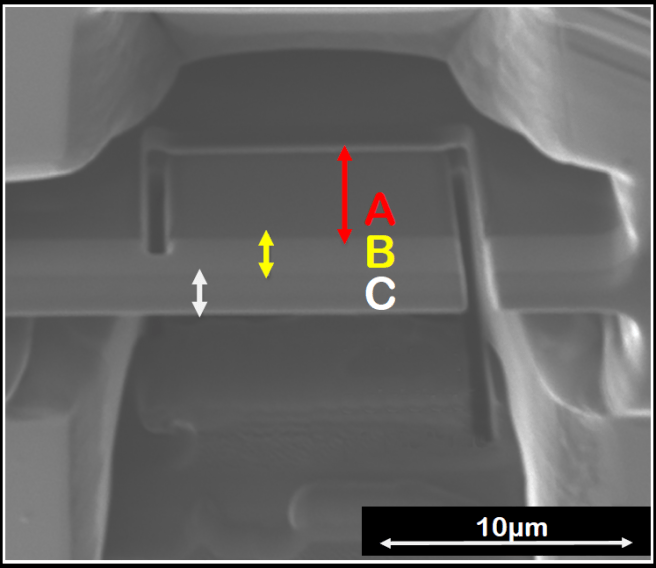

[7] TUNES, Matheus A.; VISHNYAKOV, Vladimir M.; DONNELLY, Stephen E. Synthesis and characterisation of high-entropy alloy thin films as candidates for coating nuclear fuel cladding alloys. Thin Solid Films, v. 649, p. 115-120, 2018.

Good article by my former student, Matheus Tunes.

LikeLike