In his recent work, Dr. Philip Aster delivers a remarkable contribution to the understanding of microstructural evolution in Al-Mg-Zn-Cu crossover alloys, with a particular focus on the role of copper in long-term aging (LTA) conditions.

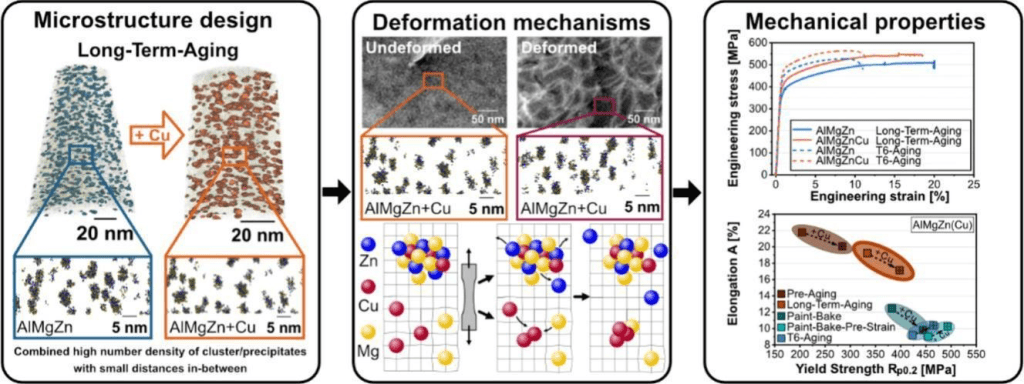

Through advanced atom probe tomography (APT), Dr. Aster demonstrates how Cu additions not only promote finer clustering and T-phase precursors but also chemically stabilise these features during early aging. This fine-scale structure effectively suppresses coarsening and enhances the alloy’s resistance to dynamic recovery. As a result, the LTA condition exhibits an impressive synergy between strength and ductility—achieving a yield strength of ~400 MPa and elongation of ~17%, outperforming conventional aging treatments in ductility while maintaining comparable strength levels.

What truly sets this study apart is the mechanistic insight into solute redistribution and its effect on strain-hardening behaviour. Using diffusion path modelling and radial distribution function analysis on deformed specimens, Dr. Aster reveals the presence of transient Zn and Cu clusters that likely underpin the observed mechanical stability during deformation. These findings not only deepen our fundamental understanding of cluster-hardening in multi-component Al alloys but also highlight LTA as a viable route for tailoring mechanical performance in demanding applications. This work stands as a benchmark for alloy design strategies aiming to reconcile high strength with superior formability.

Access the open access paper here:

Aster, Philip, et al. “Effect of long-term aging and Cu addition on clustering, strength and strain hardening in Al-Mg-Zn-(Cu) crossover alloys”. Materials & Design (2025): 114341.