Since its debut in the 1990s with the influential Oliver–Pharr method, nanoindentation has become a cornerstone of modern materials science. Originally developed to probe hardness and elastic properties at the nanoscale, this technique has since evolved far beyond its early capabilities. Today, advanced nanoindentation methods offer powerful insights into heterogeneous materials, thermally activated deformation mechanisms, and even the mechanical behaviour of materials under extreme conditions. As our materials grow more complex, so too does our toolbox for understanding them — nanoindentation remains at the forefront of this evolution.

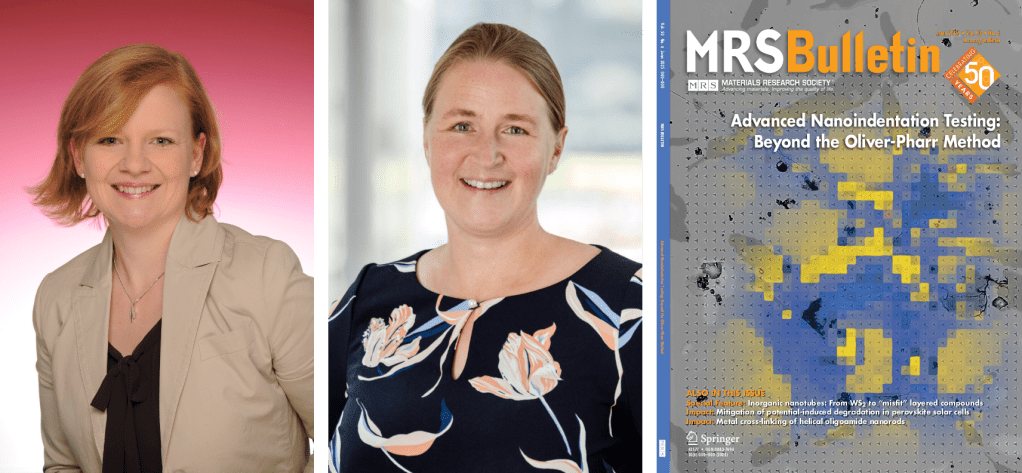

The June issue of the renowned MRS Bulletin is dedicated entirely to the latest advances in nanoindentation, showcasing its pivotal role in materials research today. A cover-feature article highlights an extraordinary article signed by both Ass. Prof. Dr.-Ing. Verena Maier-Kiener (Montanuniversität Leoben) and Prof. Dr. Sandra Korte-Kerzel (RWTH Aachen).

The Oliver–Pharr method, introduced in the 1990s, marked a turning point in materials science by enabling researchers to extract not only hardness but also elastic modulus from nanoindentation data. By linking applied load and indentation depth to determine contact stiffness, this method revolutionised mechanical characterisation at the microscale. As the field matured, it became clear that more advanced tools were needed to tackle increasingly complex challenges — such as heterogeneous microstructures, temperature-dependent deformation, and test in extreme environments (like hydrogen gas, see it here: https://doi.org/10.1016/j.actamat.2024.120113). In response, modern nanoindentation techniques have evolved into a versatile toolkit capable of probing mechanical behaviour under a wide range of conditions.

These developments now allow for precise characterisation of individual phases, composite materials, and entire system components, while also supporting high-throughput and statistical approaches. The result: a deeper, more nuanced understanding of how materials perform under real-world conditions, paving the way for the design of more resilient and efficient materials. These insights are more than academic: they play a crucial role in accelerating the development of next-generation materials, especially in fields demanding high performance under extreme environmental conditions.

This paper from Profs. Maier-Kiener and Korte-Kerzel is a must read for all metallurgists and materials scientists!

Access to the paper:

Maier-Kiener, V., Korte-Kerzel, S. Advanced nanoindentation testing: Beyond the Oliver–Pharr method. MRS Bulletin 50, 689–694 (2025). https://doi.org/10.1557/s43577-025-00921-y