Our latest research proposes a powerful new approach to designing metallic alloys with enhanced resilience under irradiation in fusion-relevant conditions.

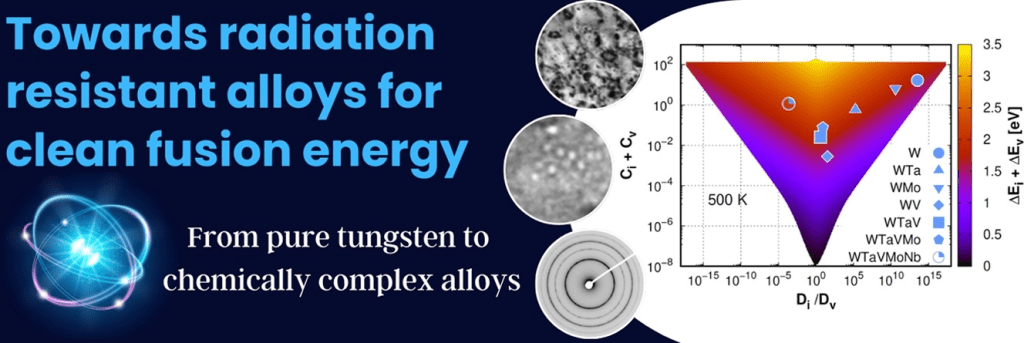

By focusing on atomic-scale defect behaviour, we demonstrate that optimal radiation resistance can be achieved when interstitial and vacancy diffusivities are closely matched, and their migration energy barriers are minimised. This combination accelerates interstitial-vacancy recombination, reducing long-term defect accumulation—one of the primary causes of radiation-induced damage.

Using rate theory and molecular dynamics simulations on tungsten-based alloys, we validate the proposed criteria and identify promising alloy candidates, particularly those incorporating vanadium and chromium. The methodology provides a predictive framework to guide alloy design, drastically reducing the need for trial-and-error experiments. This work lays the foundation for accelerated development of next-generation materials for fusion reactors, space structures, and other radiation-intense environments.

The greatest challenges on nuclear fusion relies on the science of metallurgy!

An excellent collaborative work between the Department Metallurgy at the Montanuniversität Leoben (Austria), the Department of Materials Science at Clemson University (USA), Department of Physics at the University of Helsinki (Finland), and the Reactors Materials Group at the Pacific Northwest National Laboratory (USA)

(In press) Mohammadhossein Nahavandian, Eda Aydogan, Jesper Byggmästar, Matheus A. Tunes, Osman El-Atwani, Enrique Martinez, Design kinetic parameters for improved resilience of materials under irradiation, Materials & Design, 2025, 114419, https://doi.org/10.1016/j.matdes.2025.114419.